|

Detail produk:

Syarat-syarat pembayaran & pengiriman:

|

| Material: | 304L and Carbon Steel | Pressure: | 0.1MPa – 3.6 Mpa |

|---|---|---|---|

| Media: | Toxic | Structure: | Rising thin film evaporator |

| Length: | 8000mm | Diameter: | 1500mm |

| Surface:: | 660 sqm | Weight: | 20Tons |

| Other Available Materials: | Titanium & Titanium alloy, Nickel & Nickel alloy, Copper-Nickel Alloy, Zirconium, Tantalum |

20 Tons Falling Film Evaporator 660 sqm For MDI Industry

1. Product Description

Rising thin film evaporator, also known as climbing thin film evaporator, which is operated according to the principle of siphonal pump. Based on the rising power of the vapor air bladder generated from the boiling process, liquid and vapor concurrently flow upwards, at the same time, with the rising amount of vapor, a flowing film generated on the tube wall, that is namely “climbing”, The movement of concurrent upwards is helpful to produce high-speed on flow.

It is the rising thin film evaporator’s feature that it has a long heating tube (around 5~7m), and the differential temperature between the heating box and boiling box should be wide as well, or the energy generated by vapor flow will be insufficient to feed liquid and form climbing film.

| Item Name | 304L and Carbon Steel Climbing Film Evaporator For Nitrobenzene Application |

| Application | MDI Industry |

| Tube Material | 304L and Carbon Steel |

| Shell Material | 304L and Carbon Steel |

| Diameter | 1500mm |

| Length | 8000mm |

| Surface | 660 sqm |

| Weight | 20tons |

| Other Available Materials | Titanium & Titanium alloy, Nickel & Nickel alloy, Copper-Nickel Alloy, Zirconium, Tantalum |

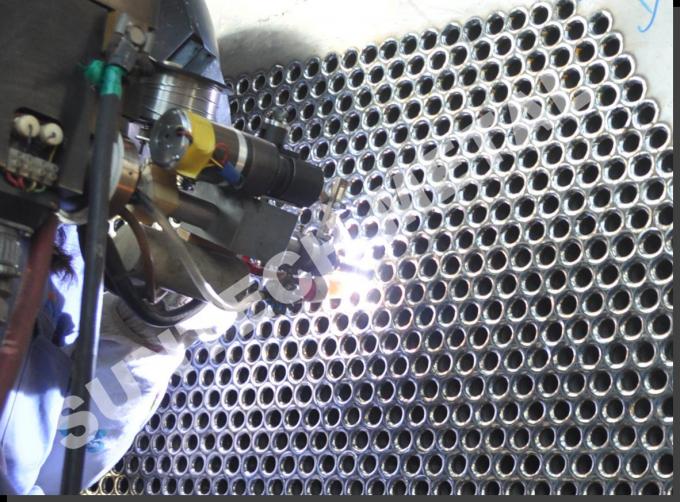

2. Production Equipment

3. Competitive Advantage:

a.Abundant experience: more than one decade of abundant experience in pressure vessel and production;

b. Technical consulting service: technical consulting on material, welding, NDE, etc;

c. Independent inspection service; in-process inspection, final inspection;

d. Transportation advantage: 296kms away from Shanghai seaport